With the continuous development of science and technology, the application of vacuum technology in the field of production and manufacturing is becoming more and more extensive. As an efficient, accurate and reliable process technology, vacuum technology has also been widely used in the field of brazing, and vacuum brazing furnace is one of the representative equipment.

Vacuum brazing furnace refers to the heating of workpieces in a vacuum chamber, which is used for welding of high-quality products and easily oxidized materials. Vacuum brazing furnace is a mechanical equipment that uses copper wire to heat and melt to complete welding. The vacuum brazing furnace is not only suitable for the connection of the same material, but also suitable for the connection of dissimilar materials, which greatly expands the application range of materials.

1. The basic principle of vacuum brazing furnace

Vacuum brazing furnace is a kind of equipment that uses vacuum environment for brazing. In a vacuum environment, the solder can better wet the surface of the material to be brazed, while avoiding the existence of unfavorable factors such as oxidation, thereby improving the quality and reliability of the brazed joint.

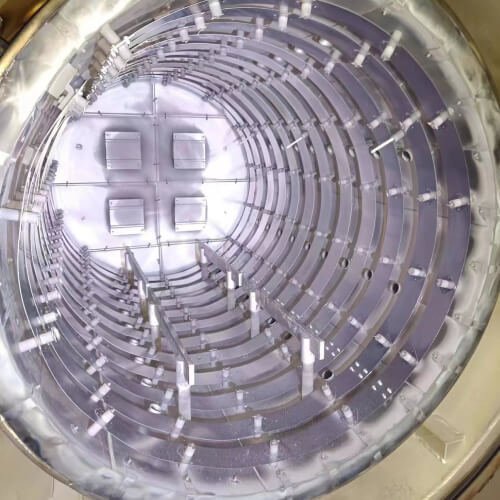

Vacuum brazing furnace is usually composed of high vacuum system, heating system, temperature control system, vacuum pump system, gas control system and so on. Among them, the high vacuum system is used to concentrate the vacuum inside the furnace to remove the gas and gaseous impurities under atmospheric pressure; the heating system is used to heat the workpiece and solder to a certain temperature, which is conducive to brazing; The temperature control system is used to control the heating system to ensure that the temperature of the workpiece and solder is controlled within a certain range; the vacuum pump system is used to maintain a high vacuum state and discharge the gas and moisture poured into the furnace; the gas control system Used to adjust the type and flow of gas poured into the furnace.

2. Application of vacuum brazing furnace

Vacuum brazing furnaces are widely used in electronics, microelectronics, aerospace, military, medical and other fields. In the electronics industry, vacuum brazing furnaces are used to manufacture high-power electronic components and high-quality electronic vacuum tubes. In the microelectronics industry, vacuum brazing furnaces are used to manufacture high reliability semiconductor packages. In the field of aerospace, vacuum brazing furnaces are used to manufacture various aero-engine parts, stress bearings, conduits, hydraulic cylinders, etc. of high-speed aircraft; in the field of military industry, vacuum brazing furnaces are used to manufacture various high-pressure, High-temperature, high-precision mechanical parts; in the medical field, vacuum brazing furnaces are used to manufacture various medical devices.