Chinaequips sinter HIP furnace can realize Vacuum dewaxing, Negative (Ar gas) differential pressure dewaxing, and H2 gas micro-positive pressure dewaxing (with a flowing H2 burn-off system).

H2 micro-positive pressure dewaxing introduces the directional flow of hydrogen in the sinter HIP furnace.

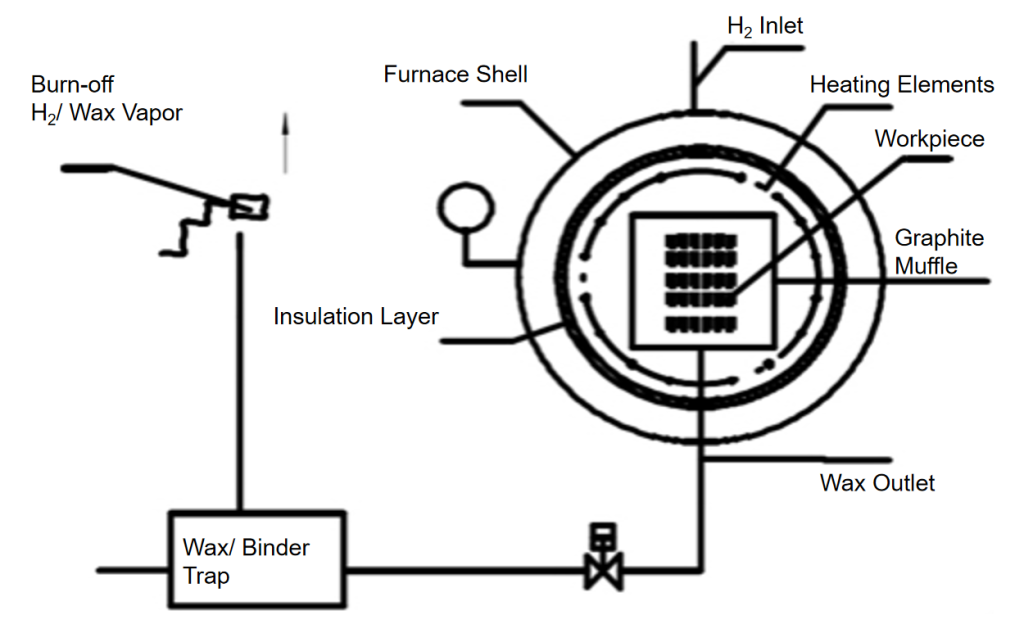

H2 micro-positive pressure dewaxing introduces the directional flow of H2 in the whole dewaxing process under micro-positive pressure (3 000 Pa higher than the atmospheric pressure). The mixed gas of hydrogen and paraffin is discharged into the air through combustion. Its schematic diagram is shown in Figure 1.

Many factors affect product quality during sintering, among which wax removal is very important. In the process of pressing and forming cemented carbide, it is necessary to add an appropriate amount of forming agent. But these forming agents only work on the forming process without any influence on the internal quality of the final product. The forming agent is not completely removed if the removal method is improper. It remains in the product as carbon or its compounds during the subsequent sintering process. This will affect the overall carbon control of the article. The effect of total carbon control plays an important role in the quality of alloy products.

H2 micro-positive pressure dewaxing in the sinter HIP furnace characteristics:

- During dewaxing, the furnace is filled with directional hydrogen. The heat transfer mode will be dominated by convection.

- During dewaxing, control the pressure in the furnace with PT1.

- There is a graphite box in the furnace. After dewaxing, a small amount of paraffin remains in the furnace.

- The dewaxing rate can reach 90%.

Disadvantages:

- Because hydrogen has decarbonization properties, the selection of H2 flow should be based on many production experiences.

- The heat transfer rate of hydrogen is fast, and it is easy to make the temperature in the furnace fluctuate in the upper, middle, and lower layers.

- Since hydrogen is a flammable and explosive gas, safety accidents are prone. Equipment needs to do a lot of safety protection measures.

- For hydrogen dewaxing, the composition of the atmosphere in the furnace is complex and difficult to control. This will lead to unstable product quality.