The existing metal tungsten extraction process generally adopts the technological approach of introducing hydrogen gas and reducing ditungsten trioxide to tungsten at high temperatures. The equipment used is mostly a four-tube reduction furnace.

The traditional powder metallurgy four-tube reduction furnace has the following defects:

- During production, the amount of hydrogen fed into the furnace must be several times higher than the theoretically calculated value to ensure the total reduction of ditungsten trioxide. Therefore, the amount of hydrogen discharged from the discharge end is enormous. Send the exhausted hydrogen to a hydrogen scrubber to remove and reuse impurities. In this way, the released hydrogen, commonly called waste gas, has taken away much heat.

- Opening the rear furnace door to take out materials and opening the front furnace door to feed materials are done manually. Therefore, it will cause to overflow when feeding and discharging materials, a large amount of hydrogen in the furnace tube, and a large amount of air enters the furnace tube. Blasting occurs when it reaches the explosion limit, causing the furnace tube to rupture or deform.

- Due to the weight of the furnace tube plus the loaded material, the frictional force between each furnace tube and the furnace body is about 400kg. At a high temperature above 900°C, heating and cooling the furnace tube frequently, causing the furnace tube to expand with heat and contract with cold repeatedly. The massive friction force hinders the thermal expansion and contraction of the furnace tube, and gradully bend and deform the furnace tube.

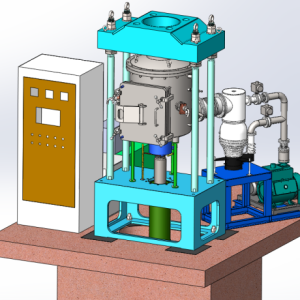

In response to the above-mentioned defects, our company has improved the design of the powder metallurgy four-tube reduction furnace:

1. Improve the utilization rate of heat energy and reduce the production cost

Arrange a waste heat utilization device between the bottom of the furnace body and the frame. The exhaust gas passes through the bottom of the furnace, increasing the tube’s temperature. At the same time, a set of hydrogen gas tubes goes through this device so that the waste heat can preheat the cold hydrogen gas before entering the furnace tube. This design improves the utilization rate of heat energy and reduces production costs.

2. Automatic feeding and discharging, improving work efficiency of the powder metallurgy four-tube reduction furnace

Set at the movable baffles at the inlet and outlet of the furnace tube to prevent hydrogen from overflowing and air entering. Use programmable technology to realize fast feeding and discharging. Set the pneumatic, hydraulic, or mechanical boat pushing methods arbitrarily for pushing the material and boat at a constant speed.

3. Install an automatic telescopic protection device to prolong the service life of the furnace tube

Adding an automatic telescopic protection device can prevent the furnace tube from being bent and deformed during thermal expansion and contraction. It avoids furnace tube blockage and rupture and prolonging the service life of the furnace tube.

Send an inquiry to get a technical solution email: yalei@cnequips.com