In comparison with the traditional cooling method, closed-cooled vacuum induction melting furnace can effectively reduce equipment loss, save energy, extend the life of the equipment, and save a lot of money for enterprises.

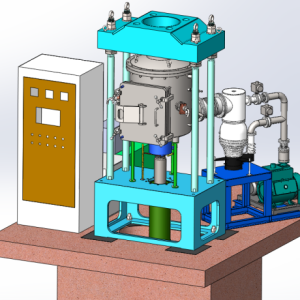

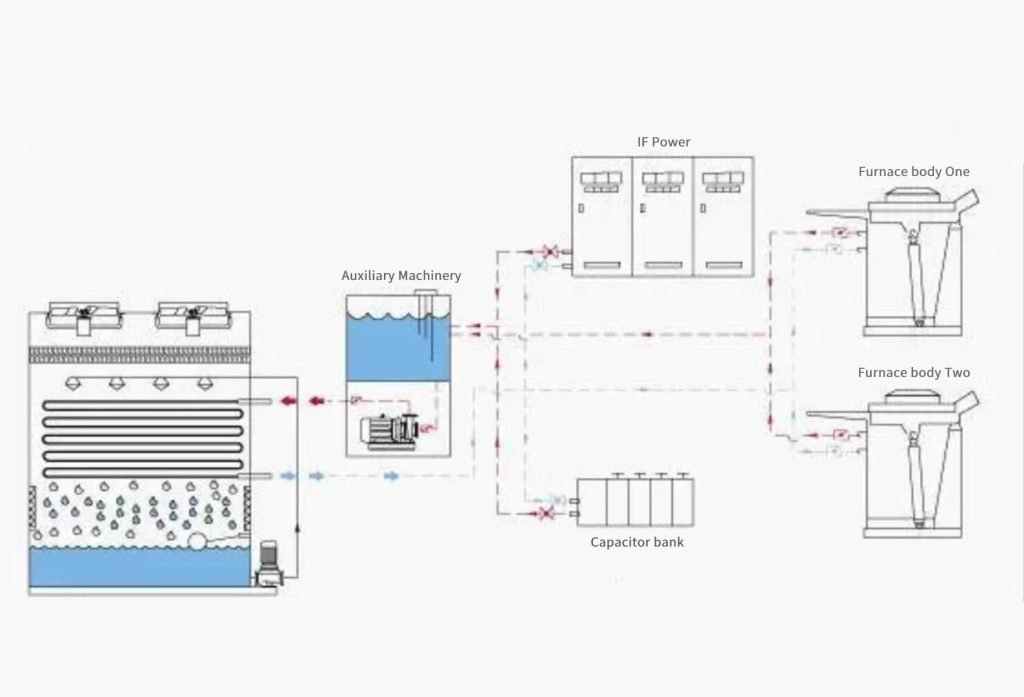

The working principle of closed-cooled vacuum induction melting furnace is:

Vacuum induction melting, also known as medium frequency electric furnace, is used for heating and melting of various non-ferrous metals. The traditional medium frequency electric furnace cooling uses fiberglass cooling tower, and the scale is serious. However, the adoption of closed-cooling tower cooling can solve this problem. The highest temperature in the furnace can reach 1750 C. It needs to rely on the cooling pipes distributed inside the furnace wall to absorb the heat continuously to protect other parts from damage. The cooling water is driven by the closed cooling tower, which can avoid the loss caused by the artificial misoperation, sacrificing part of the energy to ensure the absolute safety of the main equipment.

The cooling method of closed-cooled vacuum induction melting furnace is:

In order to improve the safety and energy saving effect of the cooling water control system, after technical improvement, the cooling water control loop is changed to the output end of the melting furnace heating switch. When the master switch is closed, the control system will not work. Only when all the preparation is ready, the heating device in the melting furnace is opened, the cooling water system starts to work. In addition, in the control loop, the timer relay is installed and the preset time parameters are used to realize the closed cooling tower to continue running for 4 hours after the heating device stops working. At the same time, a manual and automatic converter is installed in the control loop. In the normal working state, the closed tower runs or stops according to the requirements. In case of other special circumstances, the closed cooling tower stops automatically.

The advantages of closed-cooled vacuum induction melting furnace are as follows:

The improved cooling water control system has the characteristics of safety and stability, energy saving, less investment, automatic control, simple implementation and convenient maintenance, which saves water, electricity and other energy, reduces the loss of closed cooling tower and pipeline equipment and facilities, and shortens the running time of auxiliary equipment such as closed cooling tower. It can also save energy, reduce the loss of melting equipment and extend the service life of equipment, which has an important role in improving the efficiency of enterprises and saving funds.