Chinaequips sinter HIP furnace can realize Vacuum dewaxing, Negative (Ar gas) differential pressure dewaxing, and H2 gas micro-positive pressure dewaxing (with a flowing H2 burn-off system).

The differential pressure dewaxing method prevents the wax vapor from overflowing through the sinter HIP furnace chamber.

The differential pressure dewaxing method is under negative pressure. To prevent the wax vapor from overflowing through the insulation material, send a certain amount of argon gas into the outer peripheral space of the thermostat. At the same time, the inside of the box is evacuated to form a negative pressure mode of “high outside and low inside”. And it takes the wax vapor out of the furnace body.

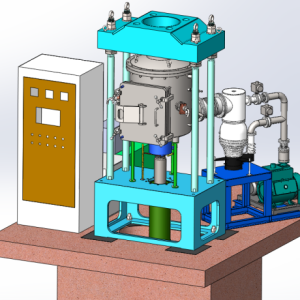

The process requires that distribute the argon gas evenly to every corner and can evenly absorb the wax vapor from every corner. It adopts the pore diffusion method here and uniformly installs the argon gas in the gas distribution pipe. It uses the argon carrier to speed up the flow of wax vapor. And discharge the paraffin vapor out of the furnace from the exhaust pipe extending into the graphite box. Figure 1 shows its schematic diagram.

We can see from Figure 1. To further prevent traces of paraffin vapor from diffusing to the heating element, heat insulation layer, and furnace wall. It adds an isolation layer (that is, a closed graphite box) around the product. Therefore, differential pressure dewaxing is a new type of dewaxing method. It forms a fixed pressure difference inside and outside the graphite box during the dewaxing process. That ensures that ΔP = PT1 – PT2 is a constant value (ΔP > 500 Pa).

To really obtain the ideal dewaxing effect in the sinter HIP furnace, it must fully considers the following points:

- Ensure the pressure difference between the inside and outside of the sealed graphite box in the furnace is above 500 Pa. Otherwise, the paraffin vapor in the graphite box will enter the furnace body, and paraffin wax will remain on the furnace wall. To prevent the pressure difference from being too low. It must do well with the heat insulation layer and the sealing of the graphite box.

- Avoid the diffusion of paraffin vapor as much as possible during differential pressure dewaxing. Use less air-permeable rigid carbon felt and graphite sheets to adjust air permeability.

- An automatic device with controllable argon flow. It guarantees that automatically complete the flow adjustment in different dewaxing stages.

- To ensure a constant pressure difference during the dewaxing process, it must be controlled by the regulating valve PV in front of the vacuum pump.

- Select an appropriate dewaxing temperature curve, and control the final dewaxing temperature within the range of 300 ~ 450 ℃. This is beneficial to shorten the dewaxing time and improve the dewaxing quality.

Negative (Ar gas) differential pressure dewaxing is an ideal method for sinter HIP furnace dewaxing. It can avoid product and furnace contamination. It can also improve the dewaxing speed and dewaxing quality, ensuring the product’s final quality. At the same time, the danger brought by hydrogen dewaxing is overcome. It has achieved good results in improving the quality of cemented carbide products, increasing production efficiency, and reducing energy consumption.