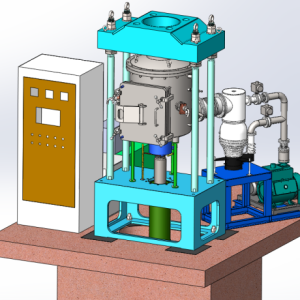

High-temperature vacuum brazing furnace is a high-precision manufacturing equipment used for brazing operations in a vacuum environment. It is mainly composed of furnace body, heating element, vacuum system, atmosphere control system and electrical control system. When using and maintaining, you need to pay attention to the following items:

1. Preparation before use

1) Installation: When choosing a place of use, you should choose a stable and firm ground, and ensure that the equipment is level with the ground. Ensure the stability of equipment and pipelines during installation. The equipment must be well grounded during installation and operation. Pipelines need to be cleaned before connection to prevent the entry of dust and impurities.

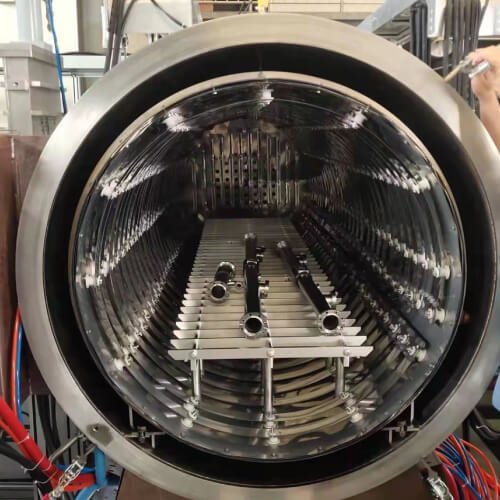

2) Inspection: Before using the equipment, check the operating status of heating elements, vacuum pumps, etc., whether the atmosphere control system, electrical control system, etc. are normal, and whether the wiring is in good condition. Before using the equipment, it is also necessary to ensure that the furnace body is clean and there is no oil on the interface, so as not to affect the use effect.

2. Precautions during operation

1) Heating: Heating is the key to the brazing operation, and heating is also one of the main functions of the brazing furnace. Before heating, it is necessary to check the state of the heating element and whether the connection is good. After the heating is successful, it is necessary to gradually increase the temperature to ensure the balance of the furnace body. According to different workpieces, the heating time and temperature should be controlled according to relevant specifications and actual production process.

2) Vacuum: Vacuum control is also an important part of the brazing operation, because the workpiece installed in the furnace needs to be in a vacuum environment before the brazing operation can be performed. During the vacuum process, it is necessary to detect the vacuum degree and find problems in time. The smooth change of the vacuum can detect some problems in advance, and then solve them in time, so as to achieve the correct brazing effect and improve the service life of the equipment.

3) Atmosphere control: Atmosphere control can be controlled according to the requirements of the workpiece to ensure the quality of brazing.

3. Equipment maintenance

1) Cleaning: The cleaning of the equipment is mainly to clean the furnace body, heating elements and pipelines to prevent failures caused by the influence of impurities and deposits. Pay attention to the safety of the equipment when cleaning. Misuse will cause serious harm to equipment and personnel.

2) Lubrication: The equipment needs to be lubricated, mainly for the lubrication of vacuum pumps and heating elements. Use appropriate lubricating materials, and be careful not to use incompatible lubricants or fill them too much.

3) Replacement: Regularly check the service life or operating conditions of the equipment, and replace worn parts or failed equipment in time if necessary to ensure the stable operation of the equipment.

The above are some basic points for the use and maintenance of high-temperature vacuum brazing furnaces. Correct use and maintenance can greatly prolong the service life of the equipment, improve the efficiency of the equipment, and bring about a more stable production process and high-quality products.