Chinaequips sinter HIP furnace can realize Vacuum dewaxing, Negative (Ar gas) differential pressure dewaxing, and H2 gas micro-positive pressure dewaxing (with a flowing H2 burn-off system).

Many factors affect product quality during the sintering process, among which wax removal is a very important part. In the process of pressing and forming cemented carbide, it is necessary to add an appropriate amount of forming agent. But these forming agents only work on the forming process without any influence on the internal quality of the final product. The forming agent is not completely removed if the removal method is improper. It remains in the product as carbon or its compounds during the subsequent sintering process. This will affect the overall carbon control of the article. The effect of total carbon control plays an important role in the quality of alloy products.

Vacuum dewaxing is in the sinter HIP furnace without any gas.

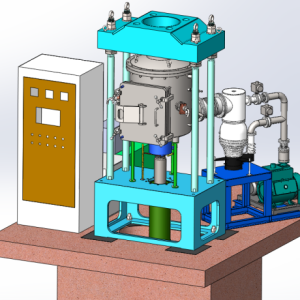

During the heating dewaxing period, the volatilized forming agent (such as paraffin) vapor is drawn out of the furnace by the vacuum system to achieve the purpose of dewaxing. Its schematic diagram is shown in Figure 1.

Features of Vacuum Dewaxing in the sinter HIP furnace

- When dewaxing, the vacuum degree is below 100 Pa, and the heat transfer method will be mainly radiation.

- During dewaxing, hot water at 60 ℃ ~ 70 ℃ is always passed through the jacket of the furnace body to facilitate the collection of paraffin on the furnace wall.

- During the dewaxing process, the paraffin vapor will fill the entire interior of the oven cavity.

- The dewaxing rate can reach 80%.

Disadvantages of Vacuum Dewaxing in the sinter HIP furnace

- During vacuum dewaxing, the heat transfer in the furnace is radiative, resulting in a large temperature difference between the edge and the center of the product. Achieving a uniform and good dewaxing effect takes a long time.

- Paraffin will condense on the insulation and furnace walls. These condensates pollute the furnace atmosphere quite seriously during the sintering process.

- Since the vacuum system takes away the paraffin vapor, it is easy to cause paraffin pollution to the vacuum system and increase the maintenance workload.

Negative (Ar gas) differential pressure dewaxing is an ideal method for sinter HIP furnace dewaxing. It can avoid product and furnace contamination. It can also improve the dewaxing speed and dewaxing quality, ensuring the final quality of the product. At the same time, the danger brought by hydrogen dewaxing is overcome. It has achieved good results in improving the quality of cemented carbide products, increasing production efficiency, and reducing energy consumption.