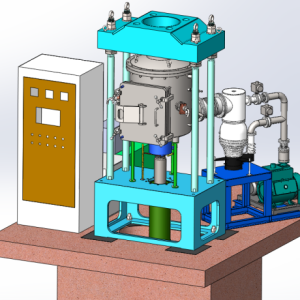

Sintering furnace dewaxing and wax collection system, the wax recovery rate exceeds 95%

The dewaxing and wax collection system is the key system of vacuum sintering furnaces, integrated dewaxing and sintering furnaces, and sinter HIP furnaces. Its main task is to lead the forming agent (paraffin) removed from the cemented carbide workpiece out of the furnace. And collect the forming agent as much as possible to avoid the pollution of the forming agent to the furnace and vacuum system. Chinaequips has designed its dewaxing and wax collection system. Its design goals are: the structure is relatively simple, and almost no daily maintenance. It can directly receive more than 95% of the input paraffin in the wax receiving tank. Paraffin contamination is barely noticeable in the furnace and main vacuum lines.

Design principle of dewaxing and wax collection system of the sintering furnace

The entire dewaxing and wax collection system, including the inner tank with a controllable process door in the furnace and the special graphite outlet pipe. It also configures a high-efficiency paraffin condensation collection system outside the furnace. This system is especially suitable for advanced low-pressure carrier gas dewaxing processes.

The paraffin vapor in the furnace goes through a dedicated outlet pipe together with the carrier gas (Ar or N2) introduced from the furnace body. Enters the collector of the wax collection (condensation) system under a moderate vacuum. About 95% of the paraffin vapor will be converted into liquid paraffin here, which will be collected into the wax collection tank. The carrier gas containing a small amount of paraffin vapor passes through the orifice and rotates it again. As the gas expands and cools down, it transforms its paraffin vapor into mist or dewdrop particles. Collect as much as possible through denser ring-shaped collection bodies. To ensure that the vacuum system is free from paraffin contamination, the carrier gas also passes through a specially designed drain condenser before entering the main vacuum pipeline.

It installs a vacuum pressure switch on the condenser to control its operating state to ensure reliable operation. To ensure the best working vacuum of the low-pressure carrier gas dewaxing operation, it installs an adjustable-diameter throttle butterfly valve with excellent adjustment performance at the exhaust port.

When removing PEG, the carrier gas will also pass through this condenser. And discharging it into the atmosphere through a special channel, and igniting and burning.

Chinaequips is also equipped with a dedicated manually adjusted constant temperature hot water circulation system for the dewaxing system.